High-efficiency Sterilization and Precise Dosing: An Industry Solution for Pipeline Ozone Generators As a leading manufacturer specializing in ozone equipment, we have accumulated extensive experience over many years.Our commitment is to provide cust...

High-efficiency Sterilization and Precise Dosing: An Industry Solution for Pipeline Ozone Generators

As a leading manufacturer specializing in ozone equipment, we have accumulated extensive experience over many years.Our commitment is to provide customers across various industries with highly efficient and reliable pipeline ozone generation systems.Leveraging advanced intelligent control technology, this equipment has been successfully implemented in numerous industrial sectors and has become a cornerstone in industrial-grade Disinfection and oxidation processes.

Core Advantages of Pipeline Ozone Generators

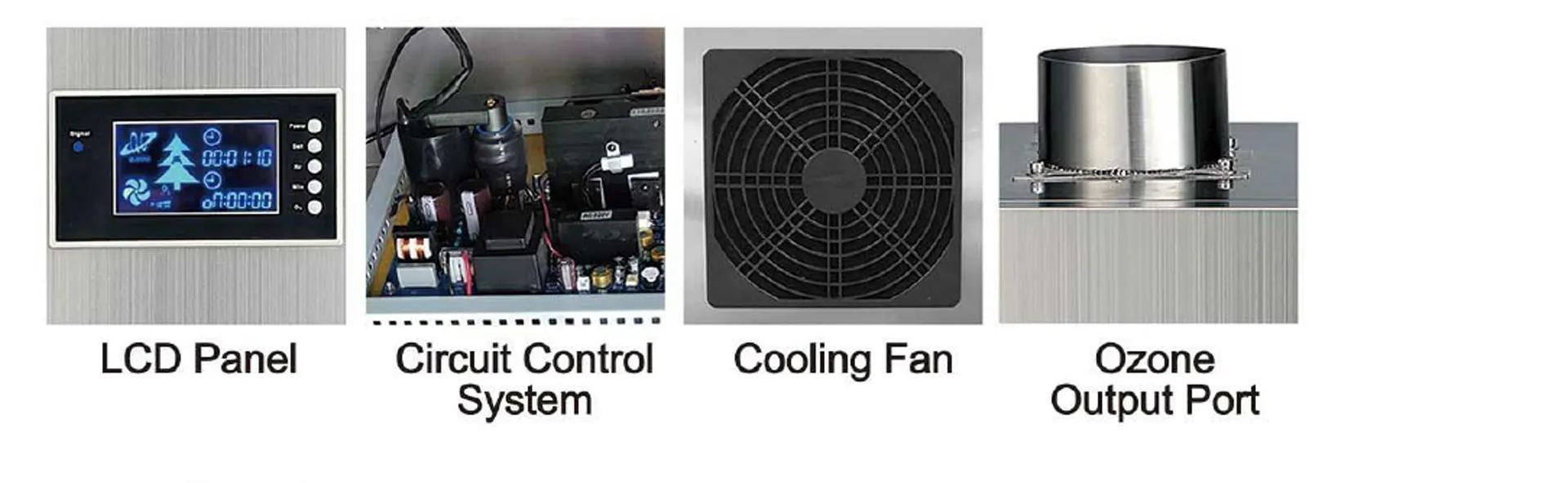

1.Precise Concentration Control

Equipped with an intelligent touch-screen control system, the device supports adjustable concentration settings ranging from 50% to 100%, along with up to 12 customizable working time configurations.This ensures precise dosing tailored to diverse application scenarios.

2.Long-term Stable Operation

The core discharge unit utilizes specialized ceramic composite materials and is integrated with proprietary power boards developed by Qlozone.This design guarantees stable output performance and extends the service life to 2–3 years.

3.Intelligent Internet of Things (IoT) Management

Real-time monitoring of critical parameters such as temperature, humidity, voltage, and current enhances operational transparency. Additionally, automated maintenance reminders ensure timely upkeep and optimal system performance.

Solutions for Typical Application Scenarios

1.Food Processing Industry

✔Air Disinfection in Production Workshops: When integrated with HVAC systems, the equipment achieves a bacterial kill rate exceeding 99%.

✔Sterilization of Packaging Materials: High-concentration ozone disinfection serves as an effective alternative to traditional chemical methods.

✔Cold Storage Preservation: Continuous processing significantly prolongs the freshness period of fruits and vegetables by 2–3 times.

✔Commercial Kitchens: Efficient removal of cooking fumes and particulates ensures air purification.

2.Pharmaceutical Manufacturing

✔Clean Area Environment Maintenance: Dynamic regulation maintains ozone concentrations within the range of 0.1–0.2 ppm, ensuring hygienic conditions.

✔Pharmaceutical Water Disinfection: A residue-free substitute for hydrogen peroxide sterilization processes.

✔Laboratory Waste Gas Treatment: Effective decomposition of volatile organic compounds (VOCs) and toxic gases.

3.Other Industrial Applications

✔Chemical Oxidation: Ideal for processes such as the synthesis of dye intermediates and fragrances.

✔Aquaculture Recirculating Water Systems: Controls pathogens in temporary breeding systems for seafood.

✔Pulp Bleaching: Replaces chlorine-based bleaches, reducing AOX emissions and promoting environmental sustainability.

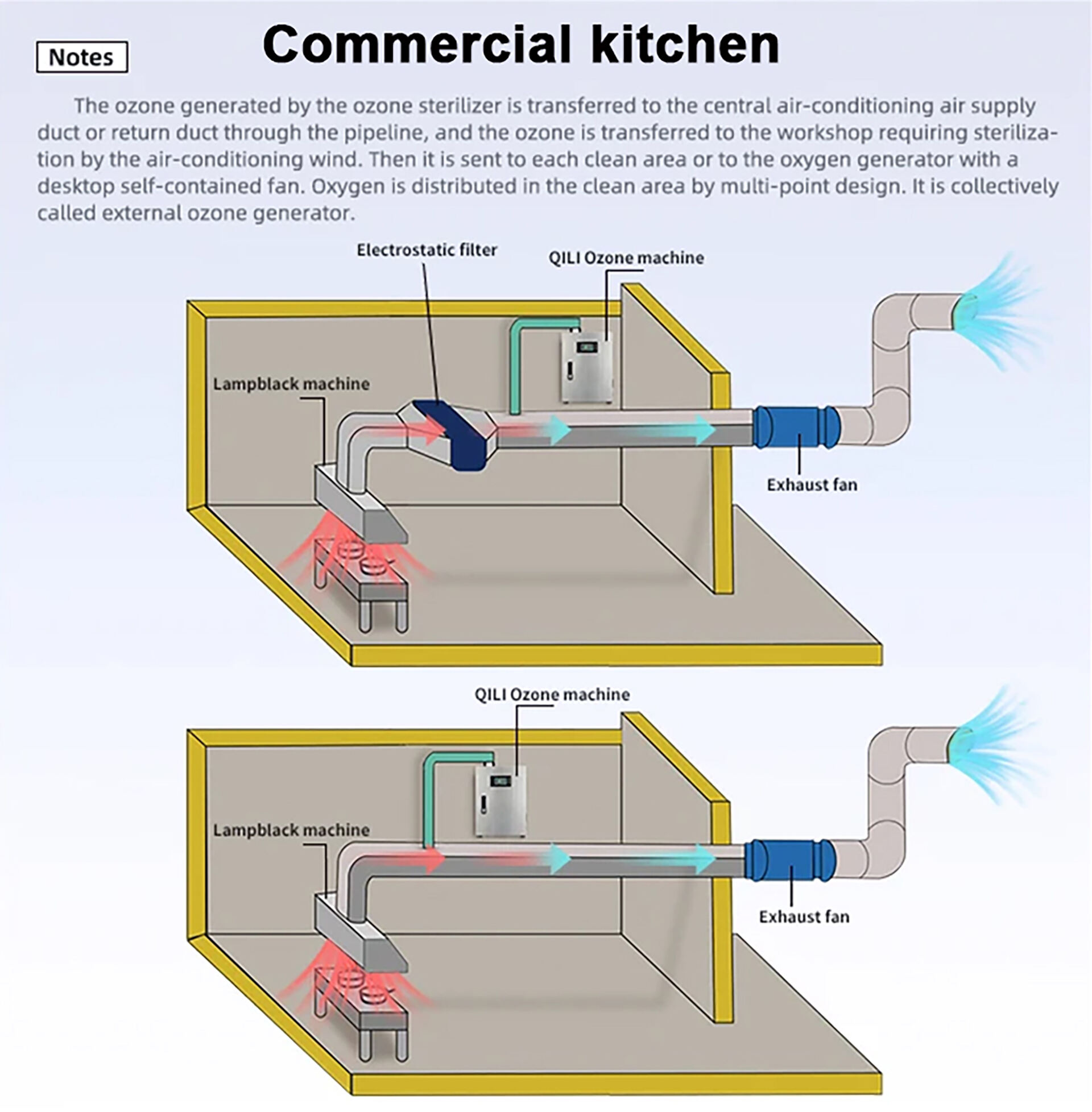

Piping organization system diagram

Pipeline ozone disinfection:

The ozone produced by the ozone generator is piped into the air duct or air duct of the central air conditioning system,and the ozone is trans-ferred to the workshop which needs to be disinfected by the wind of the space.Then it is sent to the clean areas,or the ozone is added directly to the sterilized space.The ozone is dispersed in the clean areas by multi-point design.

1.Sketch map of ventilation pipe

Wall-mounted installation,easy to operate,just connect the ozone outlet pipe to the fume pipe,in order to extend the life of the machine,as far sa possible to install the machine in a dry and venti-lated environment.

2.Schematic diagram of kitchen fume pipe

Customized Service System

We provide comprehensive services spanning the entire project lifecycle, from initial scheme design through equipment selection, installation, and commissioning;

Supports multi-level gas source treatment options (PSA oxygen generation, liquid oxygen, or air source);

Offers tailored solutions for ozone tail gas destruction devices, ensuring safe and efficient operation.